東京都水道局の水道水源林は、多摩川の上流、山梨県甲州市から東京都西多摩郡奥多摩町にまたがり、東西約31キロメートル、南北約20キロメートルに及ぶ約25,000ヘクタール(令和5年4月現在)(東京23区の面積の約4割程度に相当)の広大な面積を有しています。

当社は、この水道水源林の状況調査及び保全管理業務を行っています。

水源林の現況調査

ダムや貯水池等の水源施設は、雨水や雪解け水を貯めておくことにより、降水量の季節的変化や水道需要の変動に応じて、河川流量を調節する役割を持っています。

村山・山口貯水池は、多摩川を水源とする貯水池で、小作取水堰や羽村取水堰から取水した原水を玉川上水路を経て貯水池に貯め、東村山浄水場及び境浄水場へ導水しています。当社は、この羽村取水所、玉川上水路や村山・山口貯水池の管理業務を東京都水道局から受託しています。

スクリーン目詰まりの除去作業

当社では各浄水場において急速ろ過、膜ろ過及び高度浄水処理など、様々な水処理の浄水場の運転監視及び場内設備の維持管理業務、水質管理業務を行っています。さらに、一部の浄水場では送配水に関する調整業務、施設・機器の修繕、工事の設計・監督業務など、浄水場の運営に関わる全ての業務を担い、「安全でおいしい水の安定供給」に努めています。

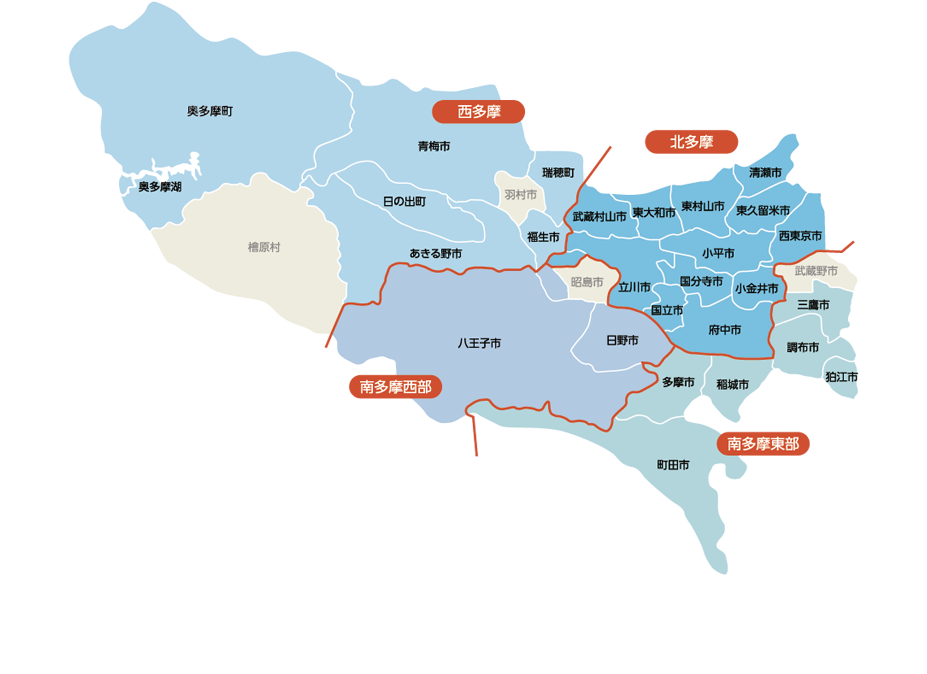

東京都水道局は、多摩地区の26市町に及ぶ広域な給水面積を有し、浄水所、給・配水所、ポンプ所、井戸水源など約600箇所の水道施設が散在しています。これらの施設を4エリア(北多摩、西多摩、南多摩東部、南多摩西部)に分けて集中管理しています。当社は24時間体制で、その運転管理業務を行っています。

広域化に対応した集中管理方式による浄水所等の運転・保全管理

当社では給水所及び増圧ポンプ所等において、電気設備、ポンプ設備などの点検や、軽微な補修作業、異常発生時の対応等を行い、「安定給水の継続」に努めています。

設備の点検